PL/X Series DC Drives

Digital 3-Phase Drives up to 2000HP+

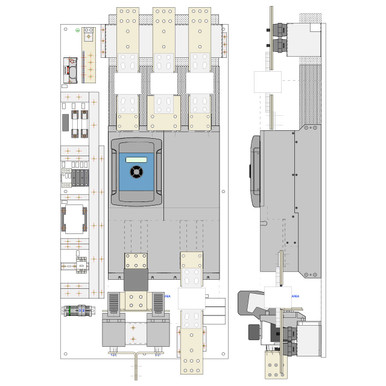

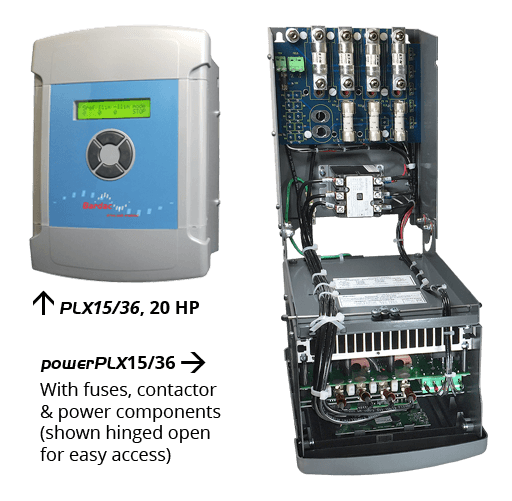

The PL/X series DC Drive is a fully digital DC drive system providing 10HP – 2000HP+ output power. Available in 2Q (single direction) and 4Q (fully regenerative) variants, the range comprises 5 compact chassis sizes with models rated from 12A to 2250A output current. The PL/X boasts an extremely versatile operating input voltage range of 12V – 500VAC as standard. Options are available for 600V and 690VAC input.

powerDRIVE Packages Come Complete with:

- Main contactor

- High speed 3-phase line fuses

- High speed armature fuse

- High speed control/field fuses

- Line filter (100HP & up)

- Optional motor blower starter (100HP & up)

Standard Features:

- Total digital control

- Basic peer-to-peer link

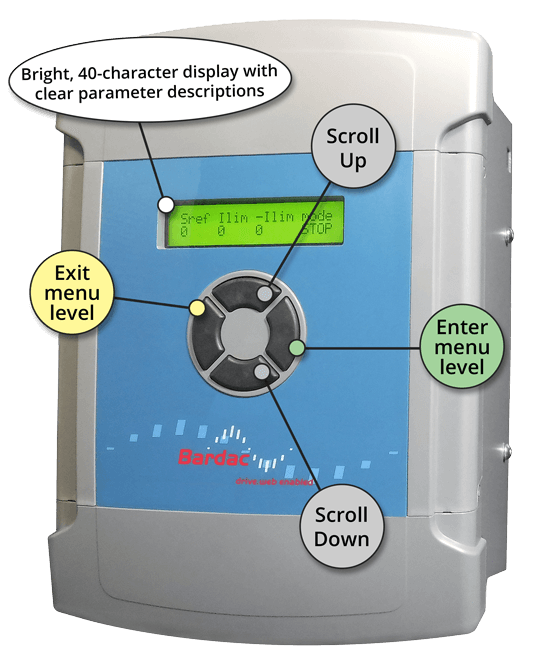

- 40 character backlit display

- Friendly, easy menu structure

- Modern, compact packaging

- Extensive, flexible, plug-in I/O

- RS232 serial port

- Easy configuration saving and cloning

- Built-in automatic field controller

- Built-in programmable control functions for PID, winders, orientation, etc.

- Tach, encoder, and arm volts feedback

- Easy reliable autotune

dw221 Ethernet and USB Included:

- savvyPanel Library

- ModbusTCP/IP Client Ethernet

- Adders, Subtracters, Multipliers, Dividers, Clamps, Switches, Logic

dw221 Options:

- Event driven email messages

- Full featured PI controllers

- EIP/PCCC Ethernet Client for Allen Bradley PLC

- Advanced Process Control & PLC

- Winder Control

- Advanced Math

Field Bus Options:

- Devicenet, Profibus DP

PL Series … easy to configure!

- Simple, intuitive configuration techniques with clear display of information

- No pots or switches to set

- Accurate display of voltages and currents

- Positive displacement push buttons for tactile feel

- High power processor and large memory will ensure ease of product enhancement in the future

- 2-button reset gets users back to OEM set up

- Powerful savvy graphical configuration, diagnostics and system design tools

Key Features:

Analog Inputs & Outputs

Field Configurations

Diagnostic Monitoring

Protection

| Digital Inputs & Outputs

Engineered Configuration Packages Pre-configured generic apps are available for Open & Closed Loop Winders, Position Controls, Coordinated Line Drives, Indexing, registration and others User Configurable Software Functions PID blocks, Parameter profiler, Winder reel diameter calculator, Winder taper tension calculator, Winder torque/inertia/friction compensator, Preset speed function, Two summers, Software “motorized pot”, Interval timer, Current profiling, Zero speed with shaft position lock, Jog / crawl functions, Two filters, Dual motor swap, Latch, Sample & hold function, Auto self-tune current loop, Linear and S-ramps, Slack take-up, Batch Counter, Draw control | Speed Feedback – Standard

Communication Ports

Included Communications

Safe, “Doors Closed” Start Up & Opertation The optional dw221 Automation Controller is embedded as standard in size 4 & 5 for easy system wide access to configure, connect, and control.

|